From limited-edition designs to unique gifts...

we make it happen.

We’re specialists in custom-printed fabrics, various wallpaper medias - Whether it is for bulk or a one-off!

We’re here to bring your designs to life in fabric. So, whether you’re a designer wanting to produce an exclusive product line, a business wanting a bespoke piece of promotional material or just want a personalised homeware gift for a friend, we can help!

We love textiles and wallpaper. But more than that, we love creating unique, custom-made prints, whether it's one-off gifts, or working in close collaboration with brands, creative people and trade partners for large quantity bulk ordering.

Make it a partnership.

We work in collaboration with our trade clients across projects from home textiles to branded items to unique fabrics for garments or work wear, including coating finishes for hygiene or health and safety. Whatever the requirement, we do whatever we can to make it happen.

Make it unique

If you’re an independent designer, purchasing for a gift, a small manufacturer or just want to add a personal touch to your textiles, just bring us your ideas, concepts and designs and we’ll make it happen. We understand your world, and why quality, reliability, and professionalism are so important.

Why not bring your idea to life with our step-by-step online order builder?

Build Your Order

Ready to make it happen?

Order custom printed products, textiles and wallpaper online – whether you’re a fashion designer, homewares creator, business or an individual looking for that perfect gift, our online custom textiles service offers the customisation options to make your items truly unique.

Order Printed Fabric

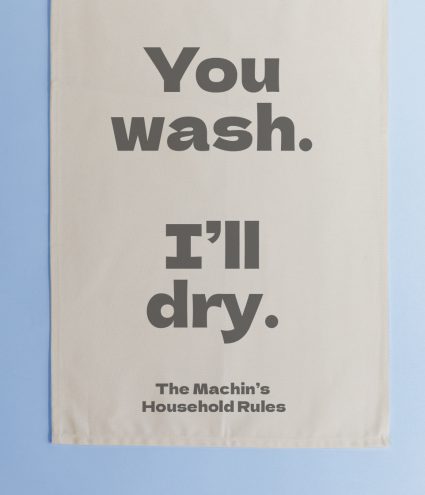

Order Printed Fabric  Tea Towels

Tea Towels  Cushions

Cushions  Oven Gloves

Oven Gloves  Adult Aprons

Adult Aprons  Child Aprons

Child Aprons  Tote Bags (Boxed Bottom)

Tote Bags (Boxed Bottom)  Tote Bags (Flat Bottom)

Tote Bags (Flat Bottom)  Washbags

Washbags  Premium Washbags

Premium Washbags

View Our Shop

View Our Shop